Understanding Raw Cashew Nut Grades: A Comprehensive Guide for Processors

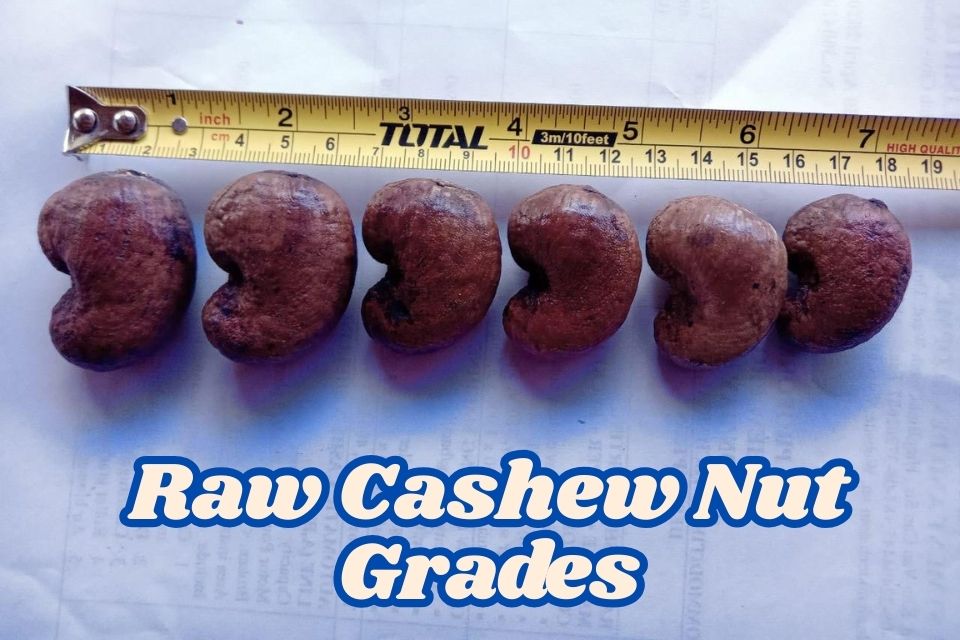

Raw cashew grading is a critical step in cashew processing that significantly impacts processing efficiency, kernel quality, and ultimately, profitability. Let’s dive deep into the world of raw cashew grades and their importance in the processing chain.

The Basics of Raw Cashew Grading

Raw cashew nuts come in various sizes, shapes, and qualities. The primary grading parameters include:

- Size (count per kg)

- Moisture content

- Foreign matter content

- Void nuts percentage

- Out-turn (estimated kernel yield)

- Defects (including immature nuts, damaged nuts, and discolored nuts)

Raw Cashew Nut Characteristics by Origin: A Global Overview

Raw cashew nuts vary significantly in their characteristics depending on their origin. Understanding these variations is crucial for processors to optimize their processing parameters and achieve maximum efficiency.

African Cashews

West African Cashews (Benin, Ghana, Ivory Coast, Nigeria, Burkina Faso)

- Generally smaller sized nuts

- Count ranges from 210-235 nuts per kg (predominantly)

- Higher moisture content (10-12%) due to humid climate

- Out-turn ranging from 44-47 lbs per bag

- Known for consistent moisture levels within batches

- Common defects: void nuts and immature kernels

East African Cashews

Tanzania

- Medium to large-sized nuts

- Count ranges from 180-210 nuts per kg

- Moderate moisture content (8-10%)

- Out-turn ranging from 48-52 lbs per bag

- Known for better kernel yield

- Premium quality in international markets

Mozambique

- Medium sized nuts

- Count ranges from 190-215 nuts per kg

- Lower moisture content (7-9%)

- Out-turn ranging from 46-50 lbs per bag

- Higher percentage of whole kernels

Asian Cashews

India

- Varied sizes depending on region

- Premium grades: 180-190 nuts per kg

- Standard grades: 190-210 nuts per kg

- Moisture content: 8-10%

- Out-turn ranging from 50-54 lbs per bag

- Known for superior kernel quality

- Regional variations:

- Kerala: Larger nuts, better quality

- Maharashtra: Medium size, consistent quality

- Tamil Nadu: Mixed sizes, good kernel yield

Vietnam

- Consistent medium to large size

- Count ranges from 180-200 nuts per kg

- Controlled moisture content (8-9%)

- Out-turn ranging from 48-52 lbs per bag

- Excellent processing standards

- High whole kernel recovery

Cambodia

- Medium sized nuts

- Count ranges from 190-215 nuts per kg

- Moderate moisture content (8-10%)

- Out-turn ranging from 46-50 lbs per bag

- Growing importance in global market

Indonesia

- Generally larger sized nuts

- Count ranges from 170-190 nuts per kg

- Higher moisture content (9-11%)

- Out-turn ranging from 48-52 lbs per bag

- Limited but growing production

Key Quality Parameters by Region

Moisture Content Range

- West Africa: 10-12%

- East Africa: 7-10%

- India: 8-10%

- Vietnam: 8-9%

- Cambodia: 8-10%

- Indonesia: 9-11%

Nut Count Range (per kg)

- West Africa: 210-235

- East Africa: 180-215

- India: 180-210

- Vietnam: 180-200

- Cambodia: 190-215

- Indonesia: 170-190

Average Out-turn (lbs per bag)

- West Africa: 44-47

- East Africa: 46-52

- India: 50-54

- Vietnam: 48-52

- Cambodia: 46-50

- Indonesia: 48-52

Impact on Processing

Cutting Machine Settings

Different regions require different calibration settings:

- West African nuts need smaller cutting blade gaps

- East African and Asian nuts require medium blade gaps

- Indonesian nuts need larger blade gaps

Steam Cooking Parameters

Variations in cooking time based on origin:

- West African: Longer cooking time due to higher moisture

- East African: Standard cooking time

- Asian: Shorter cooking time due to controlled moisture

Peeling Efficiency

Recovery rates vary by origin:

- West African: 65-70% whole kernel recovery

- East African: 70-75% whole kernel recovery

- Asian: 75-80% whole kernel recovery

Recommendations for Processors

Storage Considerations

- Segregate nuts by origin

- Monitor moisture levels regularly

- Maintain proper ventilation

- Follow FIFO (First In, First Out) principle

Processing Optimization

- Adjust machine settings based on origin

- Monitor recovery rates by origin

- Train operators on origin-specific handling

- Maintain detailed processing records

Raw cashew grading is not just a preliminary step but a crucial process that influences the entire processing chain. Proper grading ensures optimal machine performance, reduces processing costs, and maximizes kernel recovery. As the industry continues to evolve, investing in proper grading systems and understanding their importance becomes increasingly vital for processors aiming to maintain competitiveness in the global market.