The Evolution of Sustainable Cashew Processing: Advanced Pyrolysis Shell Burner Technology

In the heart of every cashew processing facility lies a fundamental challenge that has persisted for decades. The traditional method of generating steam, essential for cooking raw cashews and drying kernels, relies heavily on burning cashew shells and wood as fuel.

Introduction: The Smoke Challenge in Cashew Processing

While this practice seemingly offers a solution for waste disposal, it creates a significant environmental burden through excessive smoke emission. Processing facilities, particularly during peak seasons, often find themselves shrouded in thick smoke, affecting both worker health and local air quality.

Understanding the Traditional Process

The conventional steam generation system in cashew processing involves direct combustion of cashew shells and wood in boilers. This process, while seemingly economical due to the readily available fuel source, presents multiple challenges:

Operational Challenges

The direct burning method leads to irregular combustion patterns, resulting in fluctuating steam pressure and temperature. This inconsistency affects product quality and processing efficiency. Operators often struggle with maintaining optimal steam levels, leading to either undercooked or overprocessed cashews.

Environmental Impact

Traditional burning methods create a cascade of environmental issues:

- Heavy smoke emission pollutes local air quality

- Improper shell disposal leads to soil degradation

- Leachate from shell dumps contaminates groundwater

- Excessive carbon emissions contribute to climate change

Health and Safety Concerns

Workers in traditional processing units face significant health risks:

- Respiratory issues from constant smoke exposure

- Eye irritation and visibility problems

- Increased risk of workplace accidents due to poor visibility

- Long-term health implications from prolonged exposure

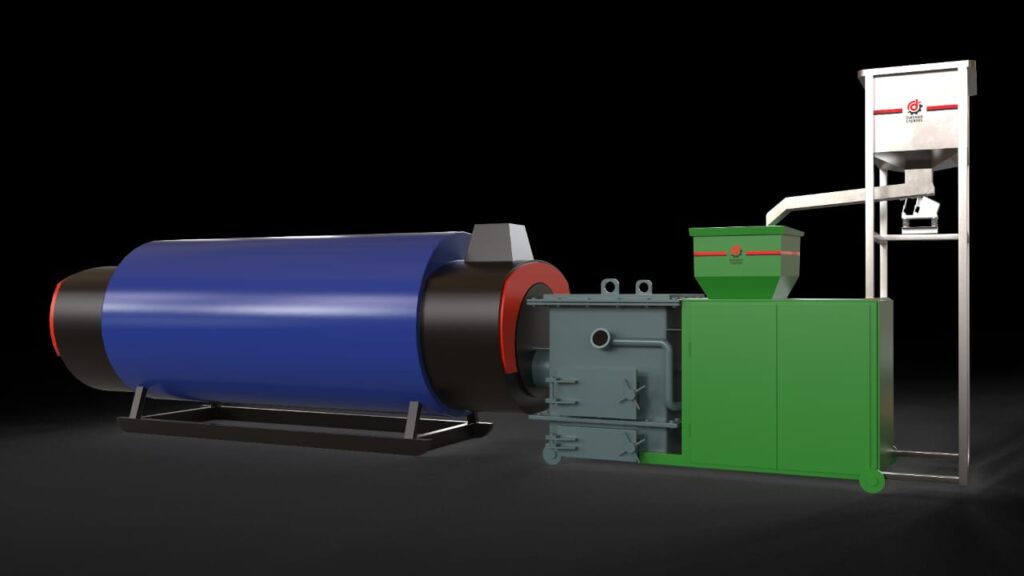

The Pyrolysis Revolution: A Technical Deep Dive

Our advanced Pyrolysis Cashew Shell Burner System represents a paradigm shift in cashew processing technology. The system’s sophisticated design addresses multiple challenges through controlled, scientific combustion.

The Pyrolysis Process Explained

Pyrolysis involves the thermal decomposition of cashew shells in an oxygen-controlled environment. This process occurs in several stages:

- Pre-heating Phase:

- Shells are gradually heated to optimal temperature

- Moisture content is reduced systematically

- Material preparation for efficient combustion

- Primary Pyrolysis:

- Controlled decomposition at specific temperatures

- Generation of combustible gases

- Formation of carbon-rich char

- Secondary Combustion:

- Burning of pyrolysis gases

- Complete combustion ensuring minimal smoke

- Maximum energy extraction

Technical Innovation Features

The system incorporates multiple technological advancements:

Automated Feed Control

- Continuous monitoring of fuel input

- Precise shell feeding mechanisms

- Optimal fuel-to-air ratio maintenance

Temperature Management

- Multi-zone temperature control

- Thermal feedback systems

- Automated adjustment mechanisms

Emission Control

- Advanced smoke reduction technology

- Particulate matter filtration

- Clean exhaust management

Implementation Success Story: Gambia Installation

Our recent implementation in Gambia serves as a testament to the system’s effectiveness. The facility, previously struggling with excessive smoke emissions and environmental compliance issues, underwent a complete transformation.

Project Implementation Phases

Phase 1: Assessment and Planning

- Comprehensive site evaluation

- Existing system analysis

- Custom solution design

- Implementation timeline development

Phase 2: Installation and Integration

- Minimal disruption to ongoing operations

- Systematic equipment installation

- Integration with existing infrastructure

- Safety system implementation

Phase 3: Optimization and Training

- System fine-tuning

- Operator training programs

- Performance monitoring

- Efficiency optimization

Measurable Results

The Gambia installation demonstrated remarkable improvements:

Environmental Impact

- 90% reduction in visible smoke

- Minimal ash residue

- Improved air quality

- Reduced carbon footprint

Operational Efficiency

- Consistent steam generation

- Reduced fuel consumption

- Lower maintenance requirements

- Improved product quality

Return on Investment Analysis

The system’s economic benefits extend beyond environmental compliance:

Direct Cost Savings

- Reduced Fuel Consumption:

- Efficient burning process

- Better energy extraction

- Lower fuel requirements

- Maintenance Cost Reduction:

- Fewer breakdowns

- Extended equipment life

- Reduced repair needs

Indirect Benefits

- Environmental Compliance:

- Meeting regulatory standards

- Avoiding potential fines

- Enhanced corporate image

- Operational Improvements:

- Better working conditions

- Increased productivity

- Higher product quality

Conclusion and Future Outlook

The Advanced Pyrolysis Cashew Shell Burner System represents more than just an technological upgrade; it’s a comprehensive solution for sustainable cashew processing. As the industry moves towards more environmentally conscious practices, this system offers a proven path forward.

Call to Action

Ready to revolutionize your cashew processing operation? Contact our team of experts for:

- Detailed technical consultation

- Custom solution design

- Implementation planning

- ROI analysis

- Environmental impact assessment

📧 Email: contact.rahul1978@gmail.com

📱 WhatsApp: +84 9086 35 704

🌐 Website: https://cashew-technology.com